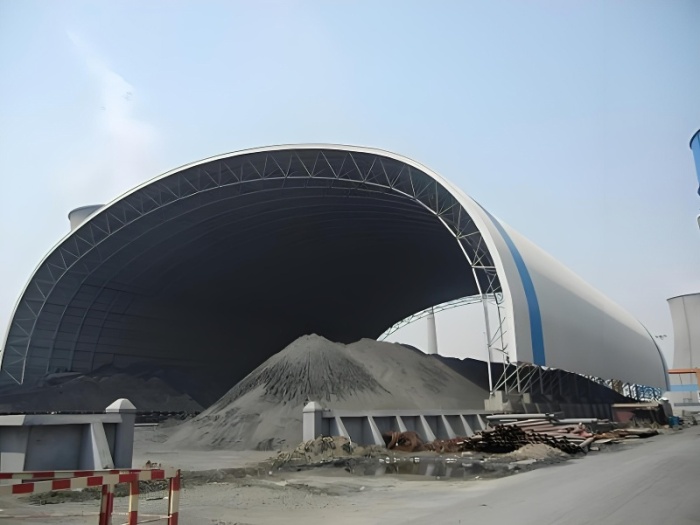

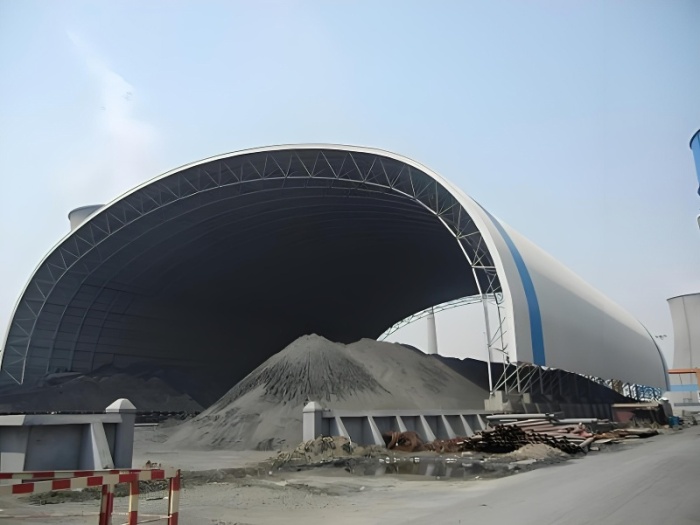

Large-span design ideal for coal depots and bulk material yards

High structural stiffness with lightweight steel members

Superior corrosion resistance for dusty and humid industrial environments

Prefabricated modular units ensure rapid installation

Fully customizable span, height, roofing, and coatings

Maintains excellent performance under wind, snow, and seismic loads

Reduces maintenance requirements and long-term operational costs

Complies with international structural standards

Supports environmentally friendly ventilation and dust-control upgrades

Designed for a 50-year service life

The Coal Shed Space Frame Roof Structure is a large-span steel roofing system specifically engineered for coal storage bases, power plants, mining facilities, bulk material yards, seaports, and logistics terminals. Compared with traditional steel trusses or reinforced-concrete roofs, a space frame system delivers outstanding strength-to-weight performance, rapid installation efficiency, and long-lasting reliability in harsh industrial environments. As coal storage sheds require wide coverage, high corrosion protection, and safe operation under heavy loads, the space frame roof has become the preferred structural solution worldwide.

This system utilizes a three-dimensional triangular grid arrangement, enabling excellent load distribution, superior rigidity, and minimal structural deformation. Its bolt-ball node connection ensures precise assembly, excellent mechanical performance, and simplified transport compared with welded structures. The modular configuration allows most components to be prefabricated in the factory, reducing on-site labor and ensuring consistent quality. This makes the space frame an ideal choice for projects requiring tight construction schedules and minimal interruption to plant operations.

Designed for industrial coal storage applications, the coal shed space frame supports long spans from 60 m to more than 120 m, creating unobstructed storage areas for efficient machinery movement and streamlined material flow. Its customizable architectural form—such as arched roofs, dome structures, straight-wall arches, and curved shells—provides excellent drainage, stable wind resistance, and optimal dust-suppression conditions. The structure can also be upgraded with environmental protection systems, including dust-control membranes, skylight panels, natural ventilation openings, and fire-resistant roofing solutions.

To withstand the corrosive environment typically associated with coal yards—where humidity, dust particles, and chemical exposure accelerate steel deterioration—this space frame system adopts high-quality Q235B or Q355B structural steel combined with robust anti-corrosion treatments. Options include epoxy zinc-rich primer, hot-dip galvanizing, anodized coatings, or fluorocarbon finish layers depending on customer requirements and local weather conditions. This greatly extends service life and minimizes maintenance costs, helping operators ensure long-term operational stability.

The roofing system accommodates a wide variety of panel materials, such as color-coated steel sheets, aluminum-magnesium-manganese panels, and PVC or PTFE membrane materials. These options provide excellent waterproofing, sunlight diffusion, and fire resistance. Lightweight roofing helps reduce overall roof weight, enabling greater spans without increasing structural cost. The space frame design ensures low deflection, excellent vibration control, and superior resilience during strong winds or seismic events.

From a safety perspective, the coal storage roof structure is engineered according to international standards, including GB, EN, and ISO structural codes. Each project undergoes precise structural calculations, simulation analysis, and customized design based on local wind load, snow load, seismic parameters, and environmental conditions. This guarantees that the industrial space frame shed provides consistent performance even in extreme climates.

Installation efficiency is one of the core advantages of the coal shed space frame. Depending on project conditions, the roof can be erected using block-by-block lifting, high-altitude assembly, or a sliding-roof installation method. This flexibility reduces crane requirements and shortens construction periods, making the structure ideal for retrofits or expansion projects where downtime must be minimized. Standardized nodes and connections allow easy replacement of individual components, further supporting long-term maintenance.

Overall, the Coal Shed Space Frame Roof Structure delivers unmatched value for industrial coal storage operations. It offers comprehensive advantages including large-span capability, exceptional corrosion resistance, superior stability, rapid erection, and customizable roofing configurations. Its 50-year service life, lower maintenance requirements, and compliance with strict structural standards make it a reliable, future-oriented solution for industrial enterprises seeking both safety and efficiency. With its combination of engineering performance and cost-effectiveness, the coal shed space frame stands out as the most efficient roofing system for modern coal storage applications.

Technical Specification Sheet

| Category | Parameter | Unit | Typical Value / Example | Description |

| Basic Information | Product Model | ton | Steel Tube | Example model (ProX Series) |

| Product Name | – | Space Frame Truss | Spatial steel space-frame |

| Brand | – | Yihong Space Frame | Manufacturer brand |

| Geometric Parameters | Total Length | Customizable | Defined by detailed design | Optimized for transport & erection |

| Single Module Length | Customizable | 1 module | Length of each prefabricated unit |

| Height (Structural Depth) | – | 31.2–40 (rise) | Maximum crown height / truss depth |

| Grid System | – | Tri-circular arch shell / Square pyramid shell | Node & member arrangement pattern |

| Span | m | 96–120 | Customizable covering capability |

| Material Parameters | Material | – | Q235B / Q33B Steel | Standard structural steel grades |

| Section Shape | – | Circular hollow section | For space-frame members |

| Section Size | mm | φ50×2 | Diameter × wall thickness |

| Surface Coating | – | Epoxy zinc-rich primer / Anodizing | Anti-corrosion protection |

| Mechanical Performance | Self-Weight | kg/m | 5.5 | Member weight per unit length |

| Max Load Capacity | kN/m² | 3.5 | Uniform load-bearing capacity |

| Allowable Deflection | mm | L/200 | Standard design limit |

| Wind Resistance | m/s | ≤30 | Maximum design wind speed |

| Connections & Nodes | Node Type | – | Bolt-ball joints | Standard bolted connection |

| Interface Type | – | Conical connector | Universal compatible interface |

| Installation & Logistics | Installation Method | – | High-altitude assembly / Block-by-block / Sliding method | Sliding method preferred for long spans |

| Module Weight | kg/m² | 30–50 | Includes steel frame + roofing |

| Snow Load | Design Basis | – | GB50583-2020, 50-year return value | Local code-based load value |

| Design Standards | Applicable Codes | – | GB50583-2020; JGJ7-2010; 07SG531 | Mandatory structural design standards |

| Coating | Protection System | – | Epoxy zinc-rich primer | Standard steel anti-corrosion treatment |

| Roof Load | – | kN/m² | 0.35 | Typical lightweight roofing load |

| Other Parameters | Design Service Life | years | 50 | Expected structural lifespan |

| Certifications | – | CE / ISO9001 | International compliance |

| Remarks | – | Custom colors available | Customization supported |