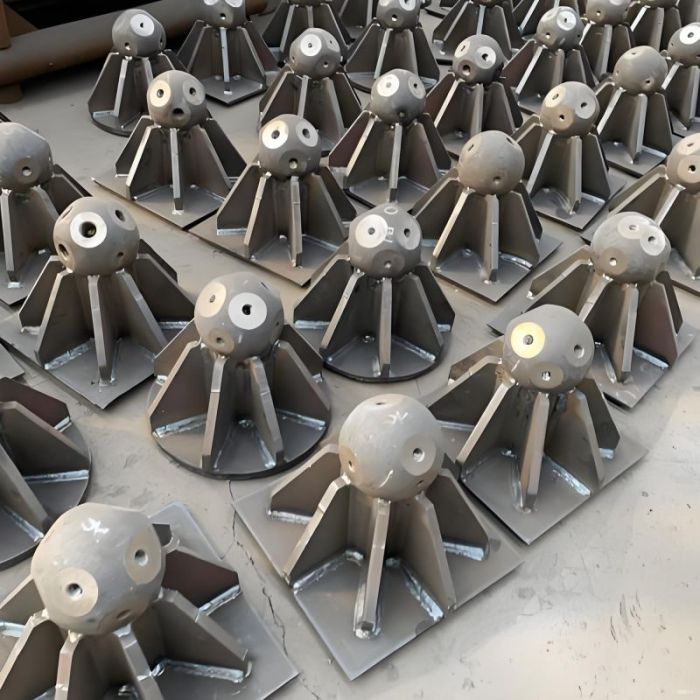

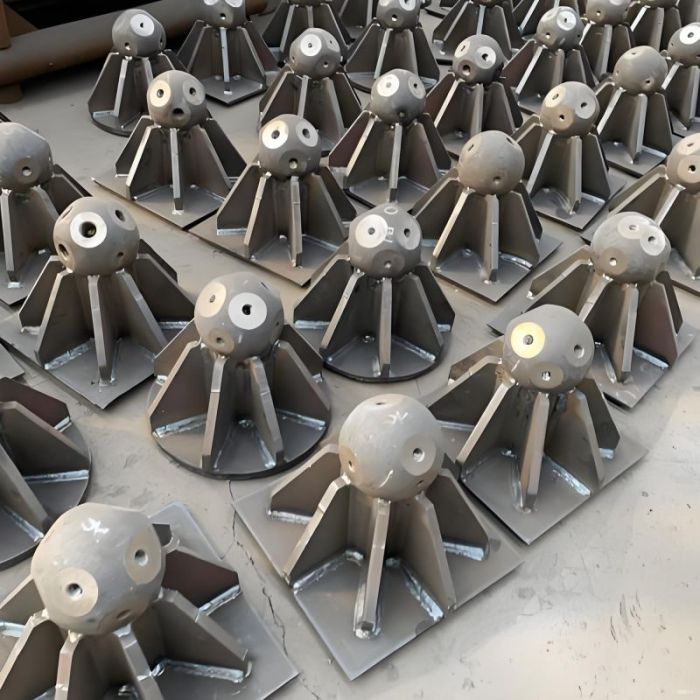

High-precision bolt-ball joints ensuring exceptional structural stability

Universal conical connector interface compatible with multiple tube diameters

Optimized for large spans such as stadiums, hangars, industrial buildings

Fast installation with modular prefabrication and sliding erection options

Durable anti-corrosion coating suitable for harsh outdoor environments

Certified quality (CE & ISO9001) for global engineering compliance

Customizable system including color, material grade, and connector specifications

The Bolt Ball Space Frame Connector System is a high-precision structural connection solution specifically designed for modern steel space-frame projects requiring durability, efficiency, and dependable long-span performance. Engineered for demanding commercial, industrial, and large-roof applications, this connector system integrates bolt-ball spherical nodes with universal conical interfaces, forming a reliable three-dimensional structural network that ensures exceptional rigidity and load transfer efficiency.

As the core connection component of a space-frame, the bolt-ball joint plays a crucial role in transferring axial forces from tubular members across the entire grid structure. Our bolt-ball connectors are manufactured using high-strength steel and precision machining to guarantee superior accuracy and alignment during assembly. The spherical geometry of the bolt ball minimizes installation errors while enabling stress to be distributed evenly in all directions, which significantly enhances the stability and safety of the overall structure. This makes the system ideal for buildings requiring wide clear spans, such as exhibition centers, logistics warehouses, aircraft hangars, coal yard covers, gymnasiums, and architectural landmark roofs.

To accommodate various project requirements, the system supports circular hollow steel tube members in multiple diameters and thicknesses. The conical connector interface ensures compatibility across standard space-frame configurations, including square pyramidal systems, double-layer grids, and tri-circular arch shells. The result is an adaptable node-to-member connection that can be customized in size, orientation, and geometric arrangement depending on the engineer's design specifications. Whether your project needs a flat roof grid or a complex curved shell, the bolt-ball system provides the flexibility and strength required for long-term structural reliability.

Durability is further guaranteed through advanced anti-corrosion coating options. Each connector can be finished with an epoxy zinc-rich primer, anodizing treatment, or customized coating system designed to withstand harsh weather, humidity, and industrial environments. These protective layers extend the lifespan of the connector and help maintain structural integrity even under continuous exposure to wind, dust, or temperature fluctuations.

Installation efficiency is another major advantage of this system. Space-frame components are prefabricated off-site, enabling rapid on-site assembly. Depending on project scale and site conditions, installation can be performed using high-altitude assembly, block lifting, or the sliding construction method—particularly effective for extremely large spans. This modular approach minimizes construction time, reduces labor requirements, and ensures consistent assembly quality.

In addition, every bolt-ball connector adheres to international and national structural design standards, including CE certification, ISO9001 quality management, and major steel-structure codes. This ensures that the product not only meets engineering performance requirements but also complies with global building regulations, making it suitable for overseas construction markets and cross-border engineering procurement.

The Bolt Ball Space Frame Connector System is engineered for a design service life of 50 years, providing peace of mind for long-term project operation. With customizable material grades, surface colors, connector dimensions, and compatible tube sizes, this product can be tailored precisely to match the demands of engineering consultants, contractors, and steel-structure fabricators. Whether you're constructing a new landmark facility or upgrading an industrial roof system, our connector system offers a dependable, efficient, and cost-effective solution for any large-span space-frame project.

Technical Specification Sheet

| Category | Parameter | Unit | Typical Value / Example | Description |

| Basic Information | Product Model | ton | Steel Tube | Example model (ProX Series) |

| Product Name | – | Space Frame Truss | Spatial steel space-frame |

| Brand | – | Yihong Space Frame | Manufacturer brand |

| Geometric Parameters | Total Length | Customizable | Defined by detailed design | Optimized for transport & erection |

| Single Module Length | Customizable | 1 module | Length of each prefabricated unit |

| Height (Structural Depth) | – | 31.2–40 (rise) | Maximum crown height / truss depth |

| Grid System | – | Tri-circular arch shell / Square pyramid shell | Node & member arrangement pattern |

| Span | m | 96–120 | Customizable covering capability |

| Material Parameters | Material | – | Q235B / Q33B Steel | Standard structural steel grades |

| Section Shape | – | Circular hollow section | For space-frame members |

| Section Size | mm | φ50×2 | Diameter × wall thickness |

| Surface Coating | – | Epoxy zinc-rich primer / Anodizing | Anti-corrosion protection |

| Mechanical Performance | Self-Weight | kg/m | 5.5 | Member weight per unit length |

| Max Load Capacity | kN/m² | 3.5 | Uniform load-bearing capacity |

| Allowable Deflection | mm | L/200 | Standard design limit |

| Wind Resistance | m/s | ≤30 | Maximum design wind speed |

| Connections & Nodes | Node Type | – | Bolt-ball joints | Standard bolted connection |

| Interface Type | – | Conical connector | Universal compatible interface |

| Installation & Logistics | Installation Method | – | High-altitude assembly / Block-by-block / Sliding method | Sliding method preferred for long spans |

| Module Weight | kg/m² | 30–50 | Includes steel frame + roofing |

| Snow Load | Design Basis | – | GB50583-2020, 50-year return value | Local code-based load value |

| Design Standards | Applicable Codes | – | GB50583-2020; JGJ7-2010; 07SG531 | Mandatory structural design standards |

| Coating | Protection System | – | Epoxy zinc-rich primer | Standard steel anti-corrosion treatment |

| Roof Load | – | kN/m² | 0.35 | Typical lightweight roofing load |

| Other Parameters | Design Service Life | years | 50 | Expected structural lifespan |

| Certifications | – | CE / ISO9001 | International compliance |

| Remarks | – | Custom colors available | Customization supported |