Customizable Design: Modular units tailored to factory layouts, spans, and heights.

High Load Capacity: Uniform loads up to 3.5 kN/m for roofing and industrial equipment.

Durable Materials: Q235B / Q33B steel with epoxy zinc-rich primer or anodizing.

Flexible Installation: Supports sliding, block-by-block, or high-altitude assembly.

Wide Application: Perfect for industrial plants, warehouses, workshops, and factories.

Architectural Versatility: Tri-circular arch and square pyramid grid systems.

Wind & Snow Resistance: Engineered for up to 30 m/s wind and standard snow loads.

International Standards: Compliant with GB50583-2020, JGJ7-2010, 07SG531, CE, ISO9001.

Lightweight Yet Strong: Optimized steel weight for easier handling and transport.

Long-Term Investment: 50-year service life for durable industrial infrastructure.

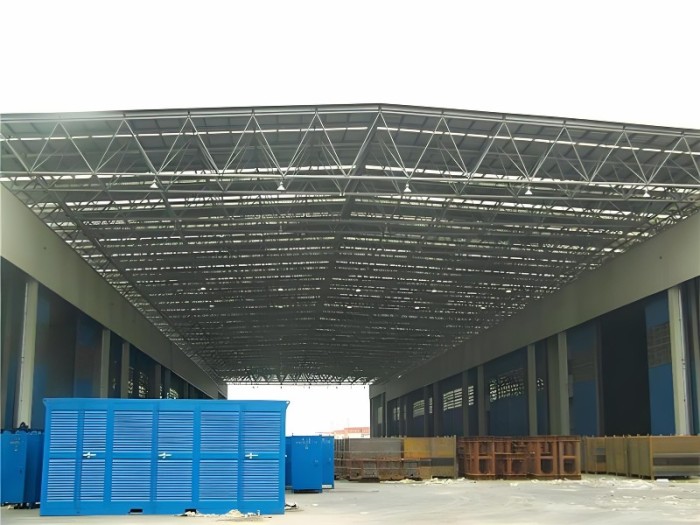

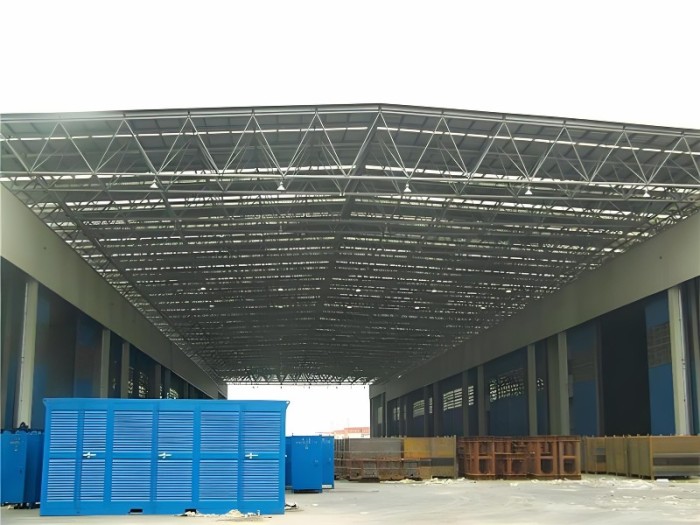

Our industrial plant space frame provides a high-performance structural solution for factories, warehouses, workshops, and other large-scale industrial facilities. Designed with modularity, durability, and structural efficiency in mind, this steel space frame allows industrial projects to achieve both long-span coverage and flexible architectural configurations. Constructed from Q235B / Q33B steel with circular hollow section members, it ensures high strength while maintaining an optimized weight, making it ideal for industrial plant space frame applications.

The system features customizable modular units that can be designed to meet project-specific requirements including total length, module size, and structural height, with spans ranging from 96 to 120 meters. Its advanced tri-circular arch shell or square pyramid shell grid system enables expansive, column-free interiors, providing maximum usability for production lines, storage areas, or assembly halls.

To ensure longevity and performance, all steel members are treated with epoxy zinc-rich primer or anodizing, offering superior corrosion resistance even in industrial environments. Each node utilizes bolt-ball joints with conical connectors, delivering precise alignment, high stability, and flexibility for diverse building layouts. The modular design allows for multiple installation methods, including sliding assembly, block-by-block construction, or high-altitude assembly, accommodating different site conditions and project logistics.

Engineered to withstand wind speeds up to 30 m/s and comply with local snow load codes (GB50583-2020), this industrial plant space frame meets international structural standards including GB50583-2020, JGJ7-2010, 07SG531, and holds CE and ISO9001 certifications. Lightweight yet strong, each member weighs approximately 5.5 kg/m, and complete modules including roofing weigh between 30–50 kg/m, ensuring efficiency in transport and on-site handling.

The frame supports uniform loads up to 3.5 kN/m, making it suitable for industrial roofing, suspended machinery, or other operational loads. Its design flexibility allows customization of grid systems, heights, and spans, enabling industrial facilities to optimize their layouts while maintaining structural integrity. The expected service life of 50 years ensures a long-term, cost-effective investment for industrial infrastructure.

Beyond performance, the system also offers architectural flexibility. The open-span design supports wide interior spaces, allowing for efficient factory layouts, storage optimization, and workflow management. With custom color options and finishes, the industrial plant space frame can be tailored to match corporate branding or aesthetic requirements.

Ideal for factory owners, industrial developers, and project managers, this modular steel space frame delivers efficiency, reliability, and durability for large industrial buildings. Whether constructing new production halls, warehouse facilities, or workshops, this solution provides

Technical Specification Sheet

| Category | Parameter | Unit | Typical Value / Example | Description |

| Basic Information | Product Model | ton | Steel Tube | Example model (ProX Series) |

| Product Name | – | Space Frame Truss | Spatial steel space-frame |

| Brand | – | Yihong Space Frame | Manufacturer brand |

| Geometric Parameters | Total Length | Customizable | Defined by detailed design | Optimized for transport & erection |

| Single Module Length | Customizable | 1 module | Length of each prefabricated unit |

| Height (Structural Depth) | – | 31.2–40 (rise) | Maximum crown height / truss depth |

| Grid System | – | Tri-circular arch shell / Square pyramid shell | Node & member arrangement pattern |

| Span | m | 96–120 | Customizable covering capability |

| Material Parameters | Material | – | Q235B / Q33B Steel | Standard structural steel grades |

| Section Shape | – | Circular hollow section | For space-frame members |

| Section Size | mm | φ50×2 | Diameter × wall thickness |

| Surface Coating | – | Epoxy zinc-rich primer / Anodizing | Anti-corrosion protection |

| Mechanical Performance | Self-Weight | kg/m | 5.5 | Member weight per unit length |

| Max Load Capacity | kN/m² | 3.5 | Uniform load-bearing capacity |

| Allowable Deflection | mm | L/200 | Standard design limit |

| Wind Resistance | m/s | ≤30 | Maximum design wind speed |

| Connections & Nodes | Node Type | – | Bolt-ball joints | Standard bolted connection |

| Interface Type | – | Conical connector | Universal compatible interface |

| Installation & Logistics | Installation Method | – | High-altitude assembly / Block-by-block / Sliding method | Sliding method preferred for long spans |

| Module Weight | kg/m² | 30–50 | Includes steel frame + roofing |

| Snow Load | Design Basis | – | GB50583-2020, 50-year return value | Local code-based load value |

| Design Standards | Applicable Codes | – | GB50583-2020; JGJ7-2010; 07SG531 | Mandatory structural design standards |

| Coating | Protection System | – | Epoxy zinc-rich primer | Standard steel anti-corrosion treatment |

| Roof Load | – | kN/m² | 0.35 | Typical lightweight roofing load |

| Other Parameters | Design Service Life | years | 50 | Expected structural lifespan |

| Certifications | – | CE / ISO9001 | International compliance |

| Remarks | – | Custom colors available | Customization supported |