Large-span, lightweight structure for station roofing

High-strength steel with long service life

Fast installation with modular space-frame technology

Fully customizable geometry, colors, and finishes

Engineered for wind, snow, and seismic resistance

Ideal for modern train stations and transit hubs

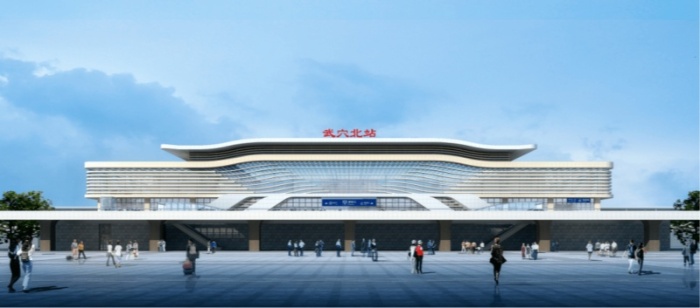

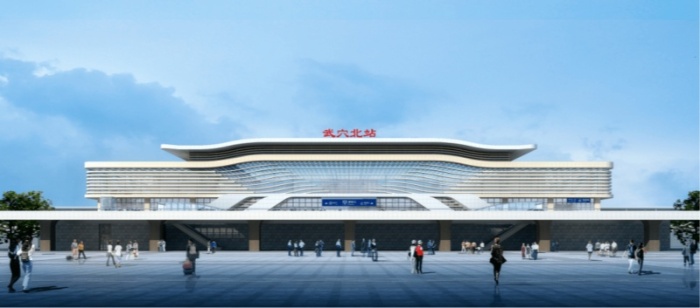

The Train Station Space Frame Roof System is a high-performance steel structural solution engineered to meet the demanding requirements of modern transportation projects. Designed specifically for large-scale public transit hubs, this advanced railway station space frame offers exceptional span capacity, architectural flexibility, and long-term durability. Its lightweight yet high-strength steel configuration makes it ideal for station concourses, platform canopies, terminal entrances, and integrated roof enclosures. Featuring precision-fabricated members, advanced anti-corrosion coatings, and secure bolted spherical node connections, this station roof structure delivers efficiency, stability, and impressive aesthetics for both new construction and renovation projects.

One of the primary advantages of this space frame system is its ability to accommodate large uninterrupted spans, which are essential for railway stations requiring open, column-free interior environments. The three-dimensional triangulated form distributes loads evenly, significantly reducing overall structural weight while increasing structural reliability. This design ensures excellent performance under extreme conditions, including high wind areas, heavy snow regions, and complex seismic zones. Engineers and project owners appreciate that the geometry can be customized to a wide variety of architectural forms—arched, domed, curved, multi-layered, or flat—making the system suitable for landmark station designs that prioritize both strength and visual impact.

The modular fabrication process greatly improves project efficiency. Each unit is prefabricated with strict dimensional control, allowing rapid on-site assembly with minimal disruption to station operations. Installation methods such as block lifting, high-altitude assembly, or sliding installation are available, with the sliding method especially recommended for long-span railway station roofs due to its safety and speed. This reduces construction time and optimizes labor costs, enabling large transit projects to be delivered faster and more reliably.

From a performance standpoint, every component is manufactured from premium structural steel with high tensile strength and predictable mechanical behavior. The steel tubes are treated with industrial-grade anti-corrosion coatings—such as epoxy zinc-rich primers—to ensure long-lasting protection in outdoor environments. Even in demanding climates, the structure maintains superior resistance to humidity, UV exposure, and long-term fatigue. The long service life of 50 years makes this solution both economically and environmentally advantageous, especially for public infrastructure investments that require low maintenance and long-term stability.

This train station space frame can also be paired with a variety of roofing materials, including lightweight metal panels, polycarbonate sheets, glass skylights, and energy-saving composite systems. The integration of drainage, skylights, MEP openings, and acoustic elements can be seamlessly incorporated into the structural design. The system's adaptability allows architects and planners to meet functional and aesthetic requirements, such as maximizing natural daylight, reducing energy usage, or achieving an iconic exterior appearance for railway stations.

Customization is offered across all engineering aspects. Span length, module size, structural depth, surface coating, and color options can be adjusted based on project demands. Whether the project calls for a curved intercity terminal entrance canopy or a wide-span high-speed railway hall roof, the space frame system supports precise design optimization. Advanced digital modeling and structural analysis ensure compliance with international building standards, guaranteeing safety and performance throughout the structure's lifespan.

In addition to technical excellence, this railway station space frame plays a key role in elevating passenger experience. Large, open indoor spaces create a sense of comfort and movement, while the elegant lattice geometry enhances the architectural identity of the station. Its superior load-bearing behavior supports heavy foot traffic, integrated signage, lighting systems, and roofing equipment while maintaining a visually clean and modern profile.

Overall, the station roof structure offers a comprehensive solution tailored for transportation engineering. Combining lightweight materials, modular construction, long-term durability, and exceptional design versatility, it remains one of the most efficient and cost-effective roofing systems for contemporary train and railway stations. Whether used for a regional transit stop or a major international interchange, this steel space frame ensures optimal performance, impressive aesthetics, and reliable structural integrity for decades.

Technical Specification Sheet

| Category | Parameter | Unit | Typical Value / Example | Description |

| Basic Information | Product Model | ton | Steel Tube | Example model (ProX Series) |

| Product Name | – | Space Frame Truss | Spatial steel space-frame |

| Brand | – | Yihong Space Frame | Manufacturer brand |

| Geometric Parameters | Total Length | Customizable | Defined by detailed design | Optimized for transport & erection |

| Single Module Length | Customizable | 1 module | Length of each prefabricated unit |

| Height (Structural Depth) | – | 31.2–40 (rise) | Maximum crown height / truss depth |

| Grid System | – | Tri-circular arch shell / Square pyramid shell | Node & member arrangement pattern |

| Span | m | 96–120 | Customizable covering capability |

| Material Parameters | Material | – | Q235B / Q33B Steel | Standard structural steel grades |

| Section Shape | – | Circular hollow section | For space-frame members |

| Section Size | mm | φ50×2 | Diameter × wall thickness |

| Surface Coating | – | Epoxy zinc-rich primer / Anodizing | Anti-corrosion protection |

| Mechanical Performance | Self-Weight | kg/m | 5.5 | Member weight per unit length |

| Max Load Capacity | kN/m² | 3.5 | Uniform load-bearing capacity |

| Allowable Deflection | mm | L/200 | Standard design limit |

| Wind Resistance | m/s | ≤30 | Maximum design wind speed |

| Connections & Nodes | Node Type | – | Bolt-ball joints | Standard bolted connection |

| Interface Type | – | Conical connector | Universal compatible interface |

| Installation & Logistics | Installation Method | – | High-altitude assembly / Block-by-block / Sliding method | Sliding method preferred for long spans |

| Module Weight | kg/m² | 30–50 | Includes steel frame + roofing |

| Snow Load | Design Basis | – | GB50583-2020, 50-year return value | Local code-based load value |

| Design Standards | Applicable Codes | – | GB50583-2020; JGJ7-2010; 07SG531 | Mandatory structural design standards |

| Coating | Protection System | – | Epoxy zinc-rich primer | Standard steel anti-corrosion treatment |

| Roof Load | – | kN/m² | 0.35 | Typical lightweight roofing load |

| Other Parameters | Design Service Life | years | 50 | Expected structural lifespan |

| Certifications | – | CE / ISO9001 | International compliance |

| Remarks | – | Custom colors available | Customization supported |